In August 2016, we were commissioned to design a new R & D center by Riso Kagaku Corporation, a company focusing on high-speed printers as its key products. The company acquired a land of approximately 20, 000 m2 to take on the challenge of creating new products and services, and decided to create an innovation center that will consolidate mechanical and chemical divisions under one roof to accelerate new developments. In October 2017, the design development was completed. The project abruptly came to a halt when the construction was about to start. The client said, "Given the future prospects, we need to reconsider this project."

As of 2022, the environment surrounding the printing industry is undergoing drastic changes due to the rapid advancement of digital technology, the repercussions of the COVID-19 pandemic, and the emergence of diverse work styles including remote work.

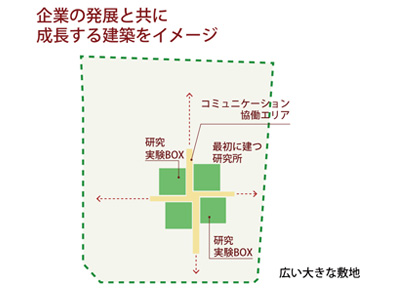

In retrospect, it appears that Riso Kagaku Corporation was keenly aware of these social changes at this stage, and felt the need to develop new products that would stay relevant in the future. In March 2018, the client contacted us again, and gave us the following requests: to create a place for the development of large printers; to build the first laboratory of about 2,000m2 while keeping the original site of 20,000m2; to provide a constant temperature and humidity laboratory of 1,500 m2 and a multipurpose room to demonstrate newly developed products; and to expand the facility as their research gains momentum. We then started to think about a new way of working and a place for collaborative creation for a company whose development policy is to "create products unparalleled in the world."

This is the first R & D center for the company producing printers to be built on a large site that they acquired

with future development in mind.

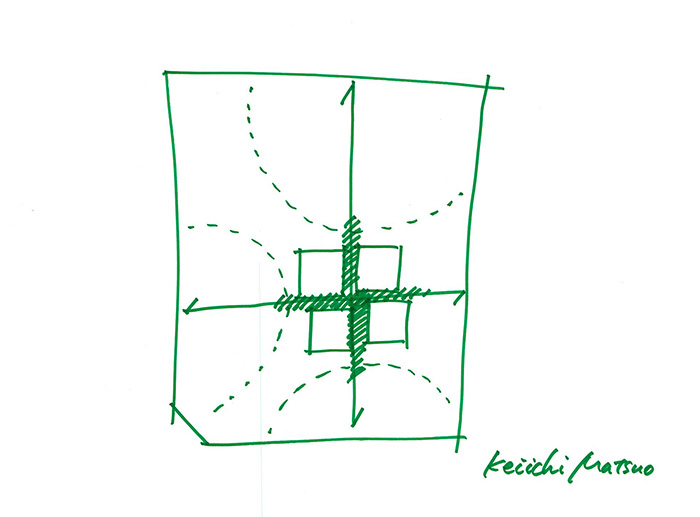

Upon restarting the project, we felt that we needed to come up with a configuration that would allow the client to envision future development in a tangible manner. In order to create the future together with the client, the architecture should stimulate the client's desire to built it.

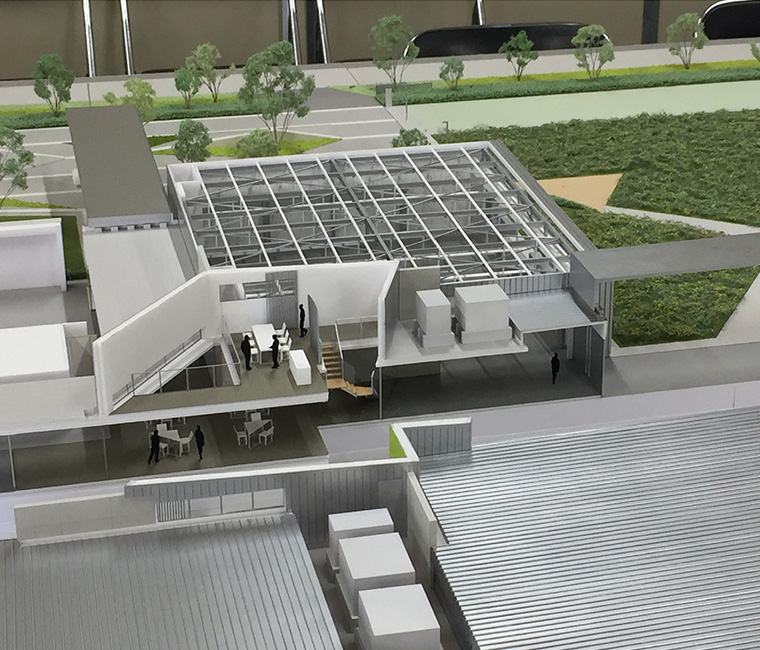

The required functions are a laboratory that can flexibly support the development of large printers, and an exhibition space to demonstrate research results. To maximize the use of the constant temperature and humidity laboratories, we came up with a floor plan in the shape of a Chinese character "田" (rice paddy), a square divided infour equal parts, using a 20m x 20m square as a unit and connecting three boxes containing laboratories and a box containing an exhibition space. The cross-shaped volume, staggered like a windmill, serves as the entrance/exit, meeting, office, and communication spaces. This configuration was envisioned as a central place surrounded by laboratories devoted to intensive research, where researchers can gather, discuss, and generate ideas for innovation.

We conceived an "architecture as a starting point" that will expand from this cross-shaped volume along with their future development.

The building was designed to express the Riso Kagaku Corporation's corporate identity and dynamism with an emphasis on security and functionality. We sought to create architecture that would motivate researchers and serve as a catalyst for development.

The design took inspiration from Riso Kagaku Corporation's high-speed printing technology. This technology, using ink cartridges that are arranged in parallel at equal intervals, transfers the color of each ink cartridge precisely and overlaps different colors to produce a beautiful print. The appearance of the ink cartridges inspired us to conceive architecture based on the idea of "stripes."

The roof and exterior walls were finished integrally with metal cladding using standing seam joints. By changing the direction of the standing seam joints that continue from the roof to the exterior walls, the same metal material gives different expressions on each box as well as the cross-shaped eaves in accordance with the direction of natural light, time, weather, and season, thereby highlighting the architectural configuration.

The cross-shaped eaves spreading out freely let us imagine how the laboratories will expand on the large site with ample surplus land in the future.

We paid attention to how the building would be viewed from the windows of the Tsukuba Express train, Metropolitan Expressway, and housing complexes and hotels. The plan in the shape of a character "田" (rice paddy) and the cross-shaped configuration like a windmill create a striking appearance that leaves a lasting impression on the viewers.

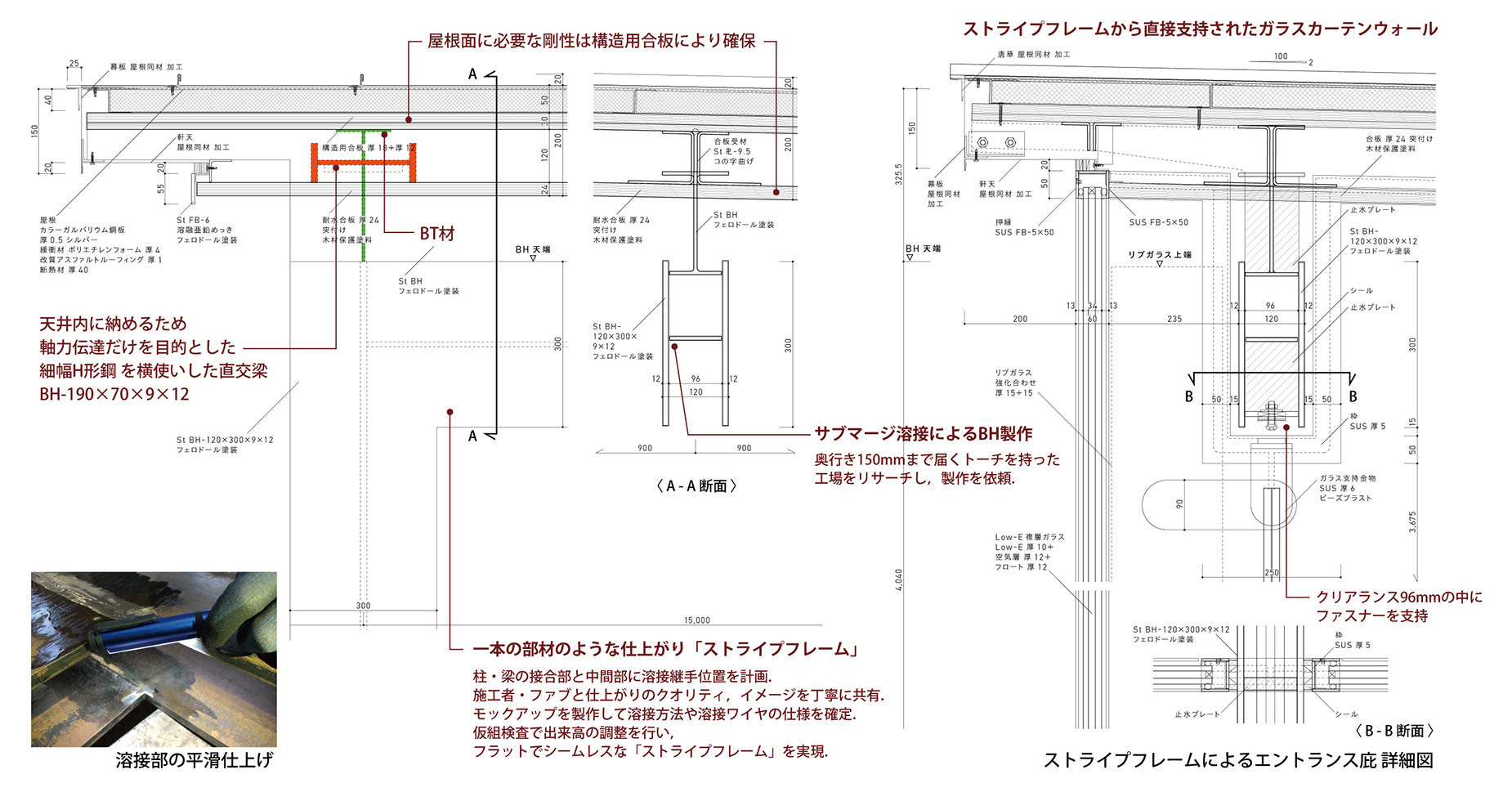

The design integrating the roof and exterior walls is shaped like a windmill that generates the winds of new development, and conveys a rich expression that changes constantly under natural light.

The entrance and the space for the demonstration of research results are constructed with a frame structure made of slender welded H-beams with cross sectional dimensions of 120mm (width) x 300mm (height), spaced at 1m-intervals. The vertical and rhythmic composition of the frame structure evokes the image of high-speed printing technology. To accommodate perpendicular beams within the ceiling plenum, narrow H-beams (190mm x 70mm)are used sideways, transmitting only axial forces. The rigidity required for the roof is achieved using structural plywood. Welded T-bars are set on top of the striped frame, and seismic forces resulting from the dead load of the welded H-beams are tranferred through rib plates set orthogonal to the welded T-bars, so that all seismic forces are borne above the welded H-beams. The welded H-beams used sideways do not need stiffening against lateral buckling, resulting in a clean frame configuration without orthogonal sub-beams along the entire length of the beams.

The glass ribbed curtainwalls are designed to support the glass directly from the stripped frame using fasteners inserted into the 96mm-clearance. The rhythmic composition of the stripes of the metal cladding on the standing seam roof, visible through the glass, echoes the colorful landscape featuring a variety of mixed tree species planted in stripes.

Downlights are also installed in the striped frame.

The development of machines requires keen attention to their mechanisms. With this in mind, we sought to create a sophisticated space with a sense of tension where everything you see is as an essential structural and functional component.

Cylindrical displacement ventilation outlets that blow in all directions to maintain constant temperature and humidity in a large space of 20m×20m with a height of 5m. They are positioned in a dispersed manner based on thermal fluid analysis to realize a large air-conditioned laboratory with constant temperature and humidity without restricting the placement of large printers that generate a considerable amount of heat. The ceiling and wall finishes were designed based on 1800mm x 1800mm modules, convenient for supporting substrate members for exterior cladding and ceiling hangers, and steel pipes of 100mm x 100mm cross section were installed. Perforated steel plates, formed into U-shapes and filled with glass wool, span the space, and high pressure wood wool cement boards, and polystyrene foam are layered on top to create a system that effectively improves sound insulation, thermal insulation, and sound absorption, thereby creating a quiet space with no condensation.

The exterior cladding system for the ceiling and walls uses square pipes and U-shaped steel plates for the substrate, eliminating secondary members such as purlins and furring strips. The 100mm x 100mm Ducts, racks, lighting, and raceways hang from the 100mm x 100mm square pipes . The ceiling details are designed to be expandable and can be added to the square pipes constituting the 1800mm x 1800mm modules.

The central part of the cross-shaped volume is raised to the second floor, creating a presentation room that brings in natural light and breezes. This room was designed as a place where researchers, who spend long hours in constant temperature and humidity laboratories, can feel the outside, thereby regulating their circadian rhythm, as well as improving their comfort level and intellectual productivity. The presentation room, co-working space, and office located in the cross-shaped volume are equipped with three types of excellent radiant air conditioning systems (ceiling panel radiant air conditioning, cast-in-place radiant air conditioning embedded for the reinforced concrete structure, and dehumidifying radiant air conditioning) that effectively achieve uniform temperature distribution and a high level of quietness, creating a comfortable and quiet space with a sense of privacy where one can feel natural light at the center surrounded by laboratories on all sides.

Dehumidifying radiant panels are installed in the natural ventilation windows to dehumidify incoming outside air, and the small amount of downward airflow generated during dehumidification allows natural airflow to circulate throughout the presentation room, office, co-working space.