RECRUIT NEWS

会社を知る About KUME SEKKEI

- メッセージ

- 社会課題への取組み

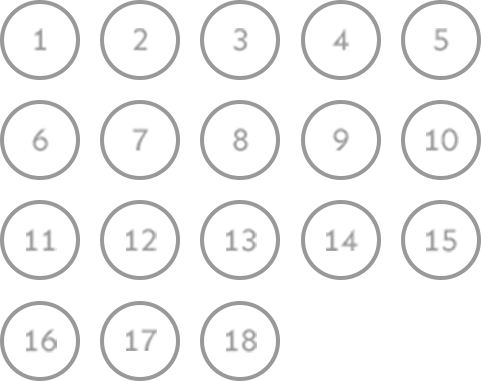

- 数字で見る久米設計

働く環境 Work @ Kume Sekkei

- ワークプレイス

- 福利厚生

- 人材育成プログラム

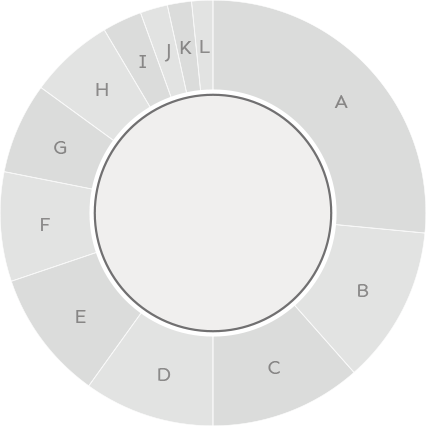

久米設計本社ビルは、久米設計社員により設計された自社ビルです。本社ビルは運河沿いに立地しており、東京でありながら風や緑が感じられる環境で業務に取組んでいます。社内には様々な設備や環境が整っています。

デザインストーリー Design Story

それぞれのプロジェクトには、関わった方々の強い想いとデザインで紡いだストーリーがあります。

プロジェクト紹介 Project

都市開発からホテルや文化施設、大学施設まで、久米設計のプロジェクトは多岐に渡ります。また日本国内に留まらず、中国やベトナムなど、海外プロジェクトにも広く携わっております。