Obihiro-Kosei General Hospital was established in 1945, moved to the former hospital site in 1955, and has been expanding its medical care functions to protect the health and lives of the residents in the Tokachi region, the largest secondary medical care district in Japan.

In November 2018, a new hospital with 651 beds was built on the current location to enhance services based on the three strategic pillars of "high-quality medical care," "medical personnel training," and "consideration for the environment."

The new hospital features a highly efficient medical function configuration and an enhanced MCP (medical continuity plan) to smoothly continue advanced medical functions in the event of a disaster, and is designed as a comfortable, disaster-resistant, and sustainable building that saves energy and reduces environmental impact.

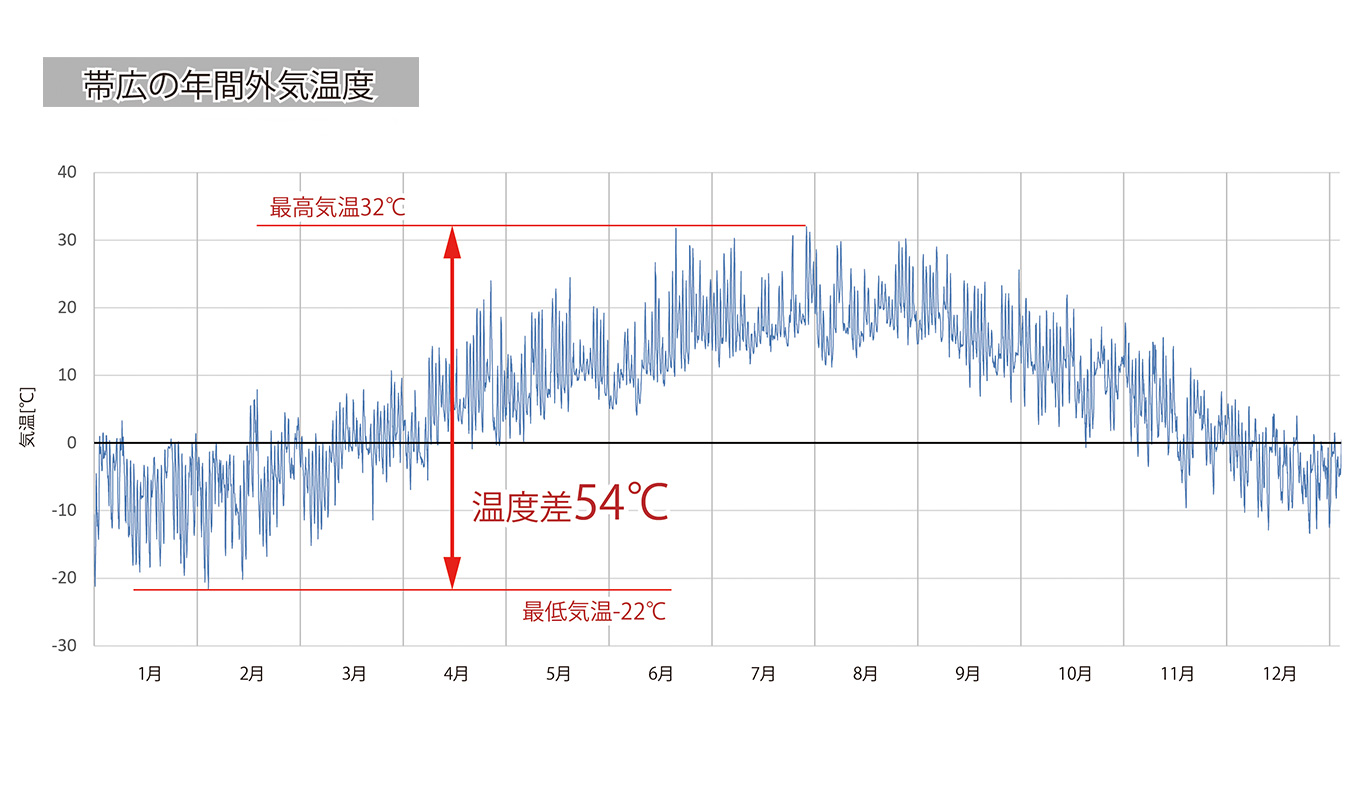

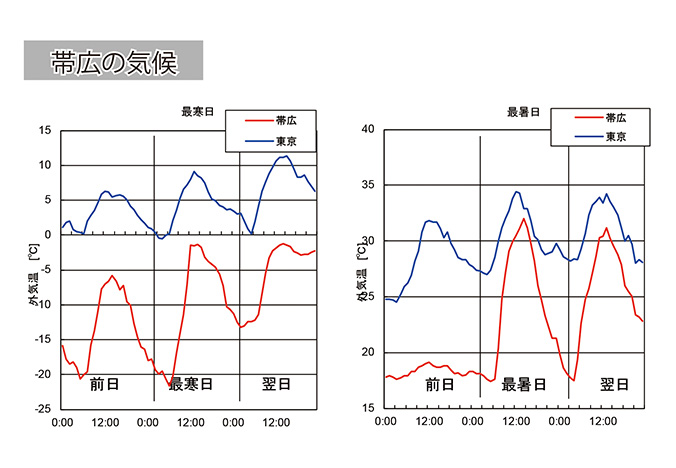

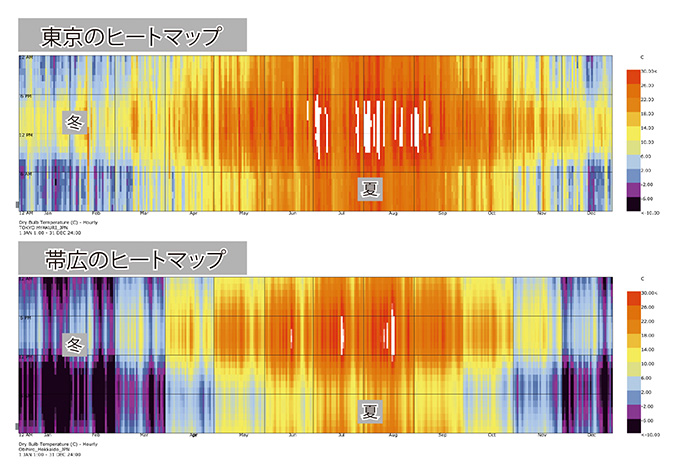

The design process begins with an analysis of the local climate.

The Obihiro area is one of the coldest regions in Japan, and also one with the biggest temperature difference between summer and winter, where the outside temperature exceeds 33℃ in the summer. The daytime temperature also fluctuates greatly, which may require air conditioning during the day and heating during the night.The region also experiences many sunny days during the winter months.

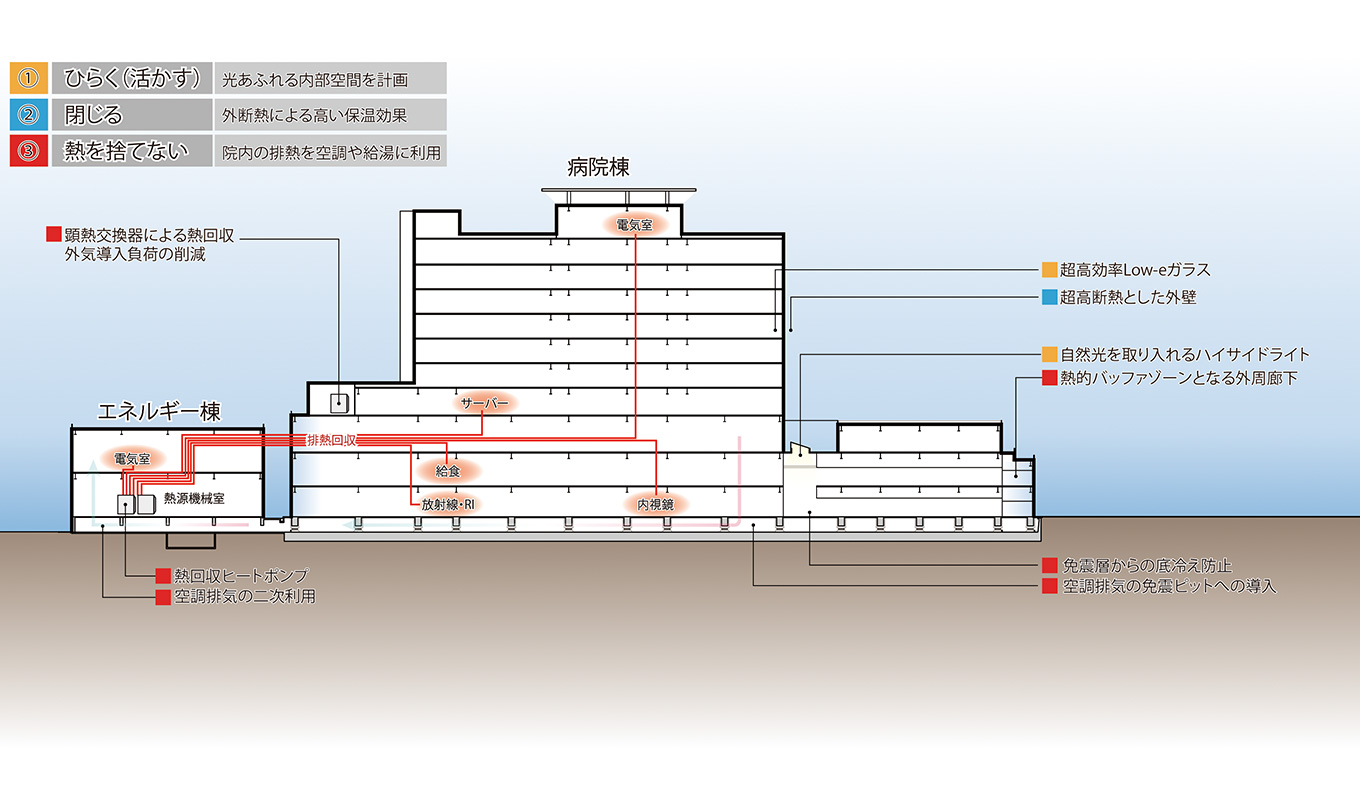

Considering the climate of Obihiro, we effectively combines the concepts of "opening" (utilizing) and "closing" for environmental planning, and "not wasting heat" in building equipment planning," in order to save energy, reduce CO₂ emissions, and contribute to the improvement of the medical care environment.

Opening (Utilizing): The light-filled interior is designed to take advantage of the abundance of sunshine in winter. Low-e glass (with a 12mm-thick air layer) and high-performance window sashes were effectively installed to prevent the penetration of cold air through the glass, cold drafts, and condensation.

Closing: A corridor along the perimeter (thermal buffer zone) was provided against the winter climate with temperatures dropping below -20℃. The exterior walls were insulated with a sprayed 60mm-thick rigid urethane layer sprayed to improve the heat retention effect.

Not Wasting Heat: To reduce the heat load in an area that requires heating for 70% of the 365 days of the year, we set the main policies of (1) fully utilizing the exhaust heat from air conditioning without waste, and (2) utilizing the exhaust heat from cooling generated within the hospital for heating without discarding it.

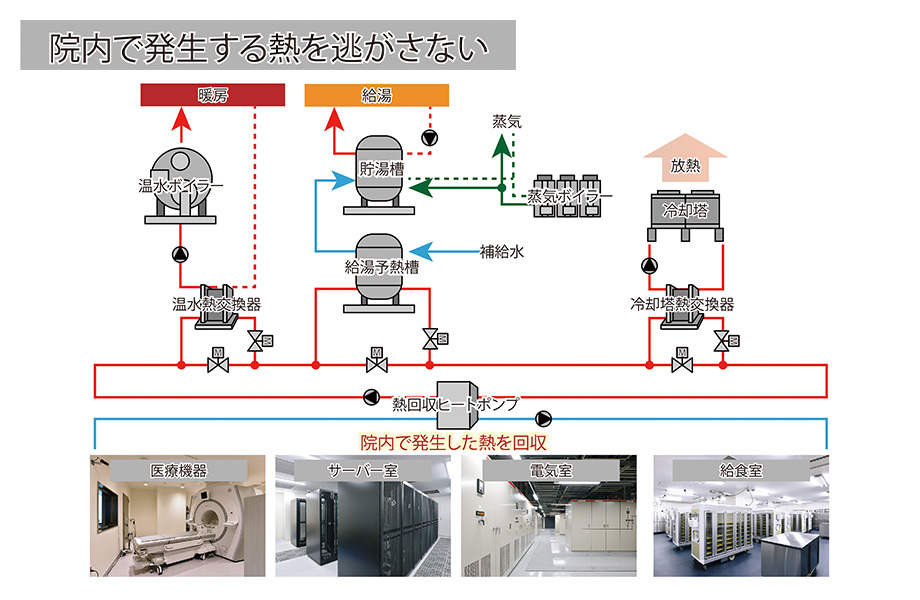

(1)Retaining the heat emitted in the hospital

While the exhaust heat from the electrical room, server room, and refrigerators is generally discharged to the atmosphere.this system uses a heat recovery heat pump to recover the exhaust heat and supply hot water for heating based on the "Mottainai" (too good to waste) thinking.

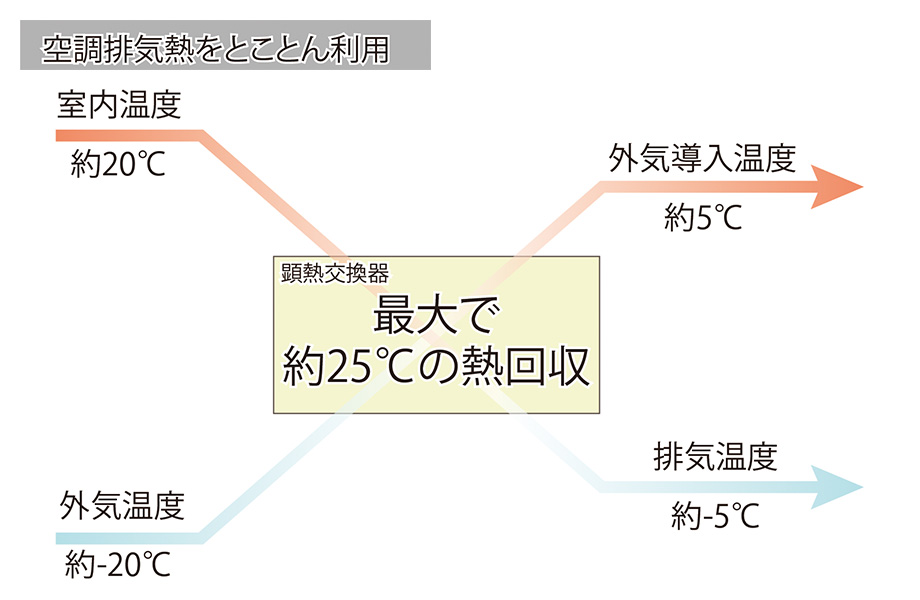

(2)Fully utilizing exhaust heat from air conditioning systems

Based on the idea that the exhaust air of around 20℃ from air conditioning systems is too good to waste, a heat exchanger is used to recover exhaust heat to warm the cold incoming outdoor air and reduce the outdoor air heating load.

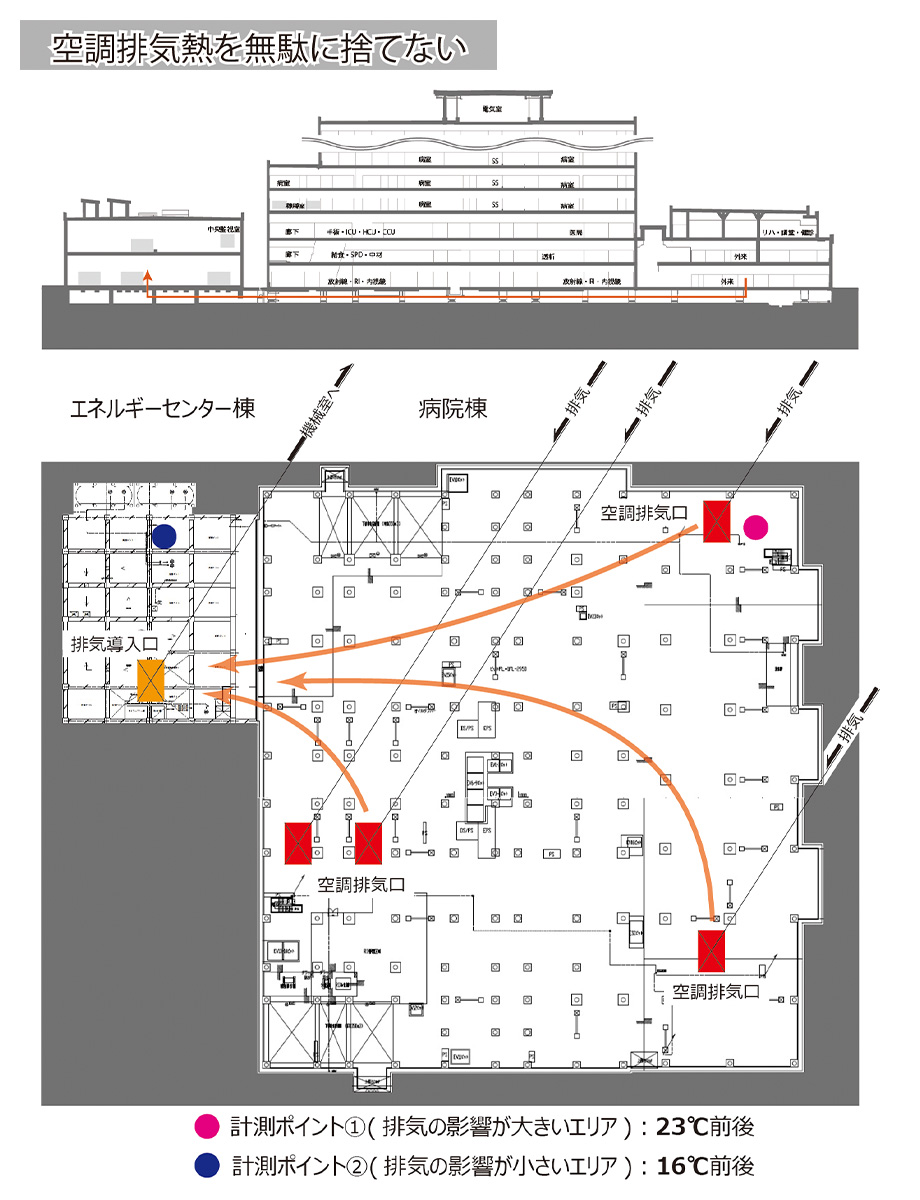

(3)Stop discharging exhaust air from air conditioning for nothing

Based on the idea that it would be wasteful to discharge exhaust air from air conditioning systems on the lower floors to the atmosphere,we led the exhaust air into the seismic isolation pit to reduce the heating load on the ground floor and thereby prevent the drop in temperature of the air inside the isolation pit.

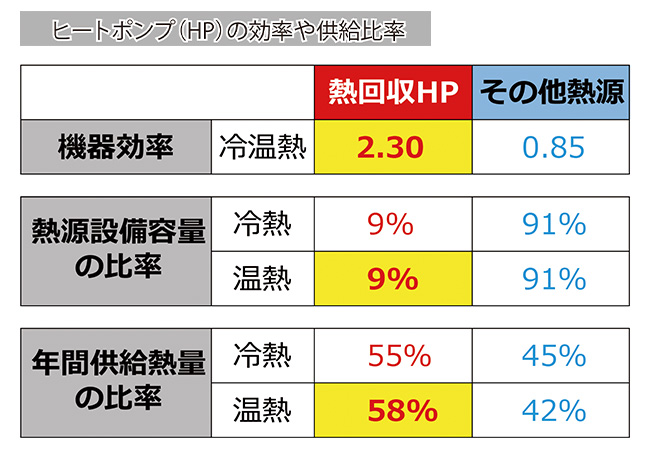

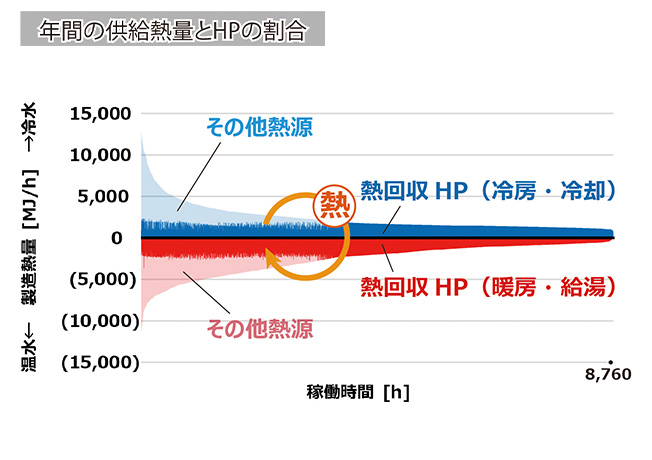

The middle row in the table on the left shows the composition of the capacity of the heating equipment. While heat recovery heat pumps account for only 9% of the total capacity, heat recovery heat pumps supply 58% of the annual heat supply as shown in the table in the bottom row. As a result, gas consumption for heating and hot water boilers has been successfully reduced, thereby significantly reducing primary energy consumption.

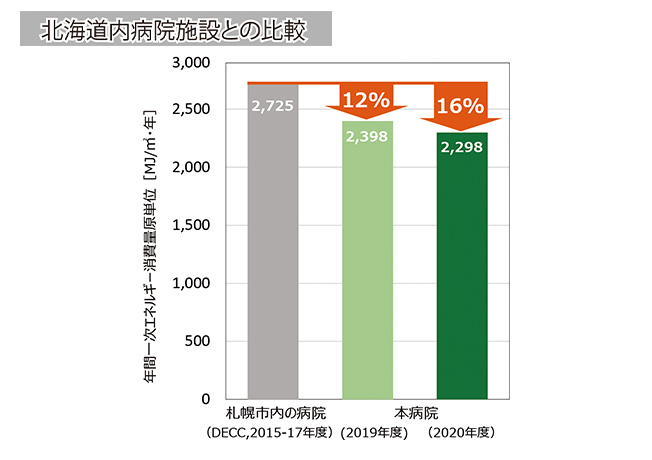

The energy consumption of Obihiro-Kosei General Hospital in 2020 was approximately 16% less than DECC's hospital facilities in Hokkaido, and 11% less than comparable hospitals in the Kanto region, indicating that the hospital is saving more energy than hospital facilities in other cold regions and the Kanto region.

The building equipment planning of the Obihiro-Kosei General Hospital was the culmination of the architect's 25 years of experience in designing medical care facilities and extensive design experience in cold climates. In my previous designs, I have found it "Mottainai" (wasteful) that the exhaust heat from electrical rooms, medical equipment, and refrigerators is discharged to the atmosphere while medical care facilities need heat sources for hot water supply throughout the year and heating in winter months. With today's advanced heat pump technology, I think we have successfully proven at the Obihiro-Kosei General Hospital that the effective utilization of exhaust heat leads to significant energy conservation. We received recognition from the Society of Heating, Air-Conditioning and Sanitary Engineers of Japan, and won the Technological Promotion Award in 2021.

Associate General Manager

Envionmental&Engineering Department

Hiroki Yokoyama