"Would you like to work on the structure of the Yamanashi project?"

On a summer day in 2009, I received a call from Mr. Noguchi. Naturally, I replied, "By all means, please put me in charge," hoping to get his recognition this time. My thoughts go back to nine years ago from this time. In the spring of 2000, Mr. Noguchi's architectural and structural teams were working on the concept design of the North Entrance of the 2005 World Exposition, Aichi, Japan, based on the themes of "change and flow" and "evolution and regression." My proposal was not well received at all. In the end, the design was put together based on a conceptual sketch by Mr. Noguchi and a structural framework proposed by structural engineer Shigeru Ban (formerly of Kajima Corporation., whose representative work includes M-Wave Nagano Olympic Memorial Arena). One of my junior colleagues who later became independent told me that Mr. Noguchi's evaluation of my proposal was very low. I believe that Mr. Noguchi contacted me because he had seen the structure of the Oita Prefecture Driver's License Center completed later.

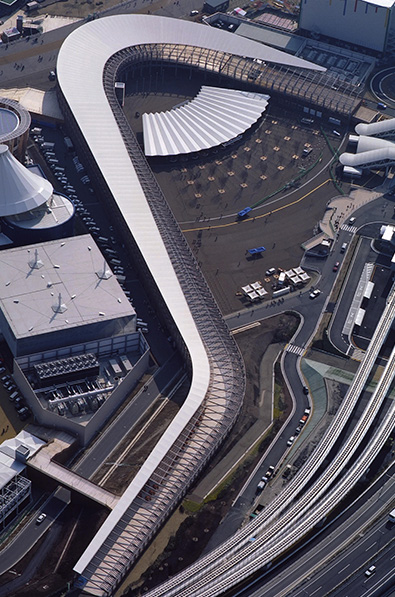

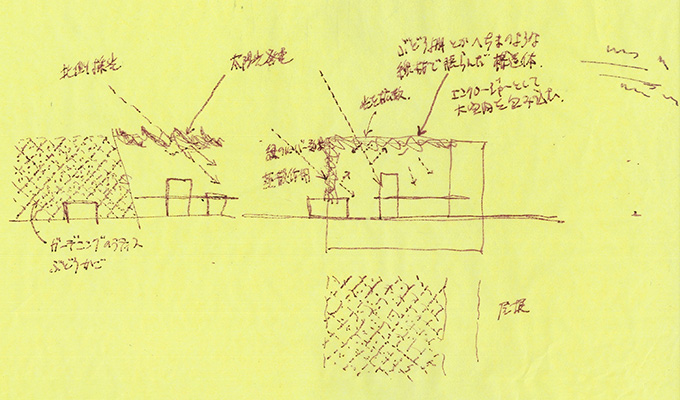

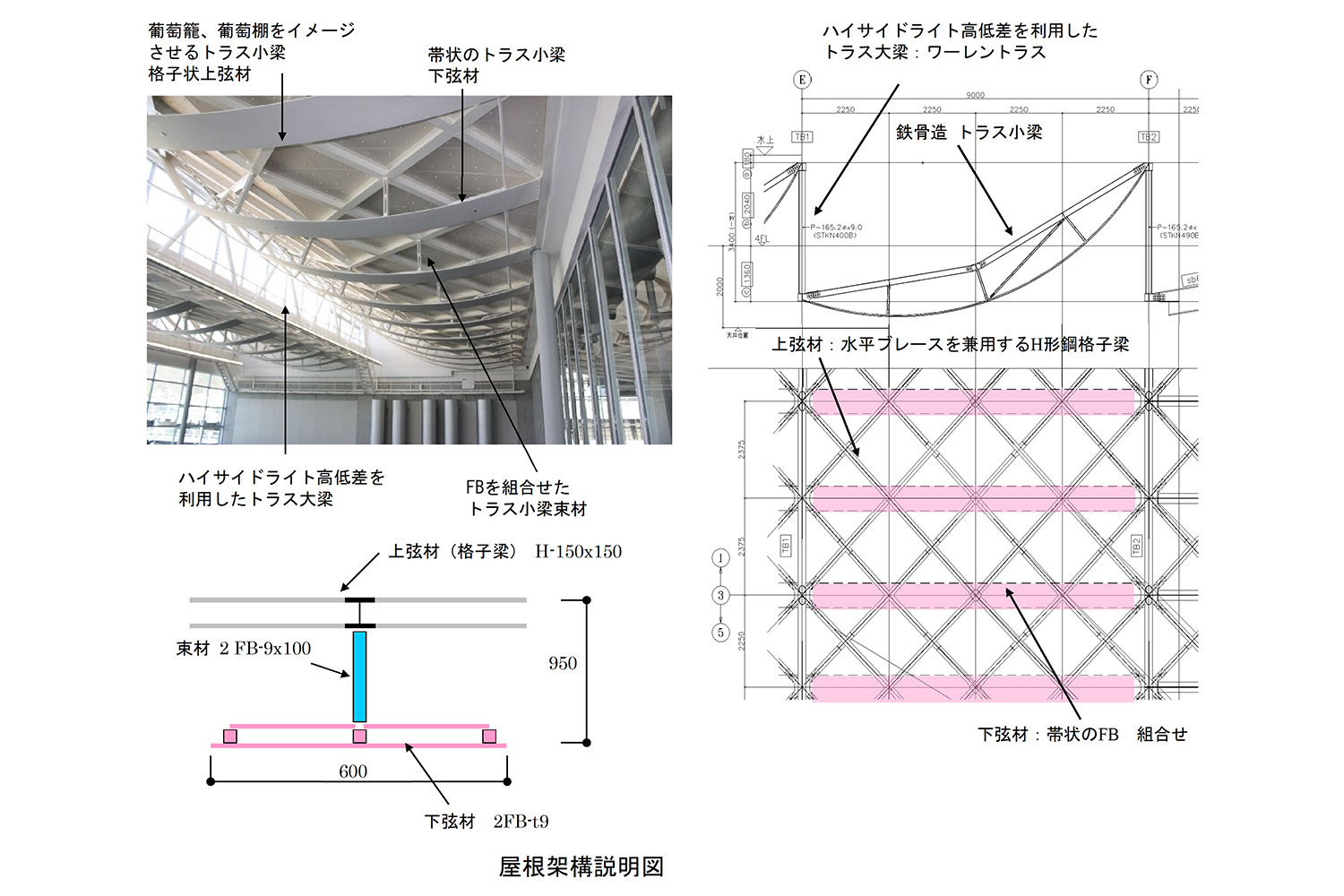

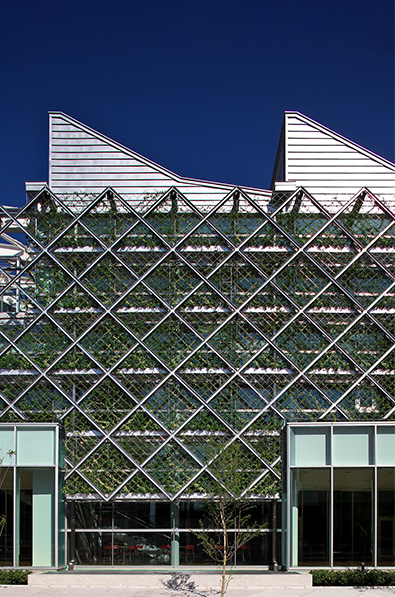

Finally, the schematic design began. Mr. Noguchi said, "The main concept is "living with nature," and we aim to create a library surrounded by curtains of greenery and blue sky, as if you have wandered into a huge orchard, where you can always feel close to nature and spend rich time, while respecting the environment through energy and resource conservation." Specifically, Mr. Noguchi wanted to wrap the entire building with cage-like lattices that cover the west and south walls and continue to the roof surface, reminiscent of the image of grape baskets and trellises that are part of the design concept, and he thought it would be ideal to utilize the cage-like lattices as structural members so that they become the design of the building itself. In order to install solar panels and bring in light from the north side of the building, the roof should have a sawtooth shape with a series of sloping sections every 9 meters in the north-south direction. Also, the reading space on the second floor with a rectangular plan of about 38.5m x 72m needs to be an open plan and two story high (about 8.5m) space.

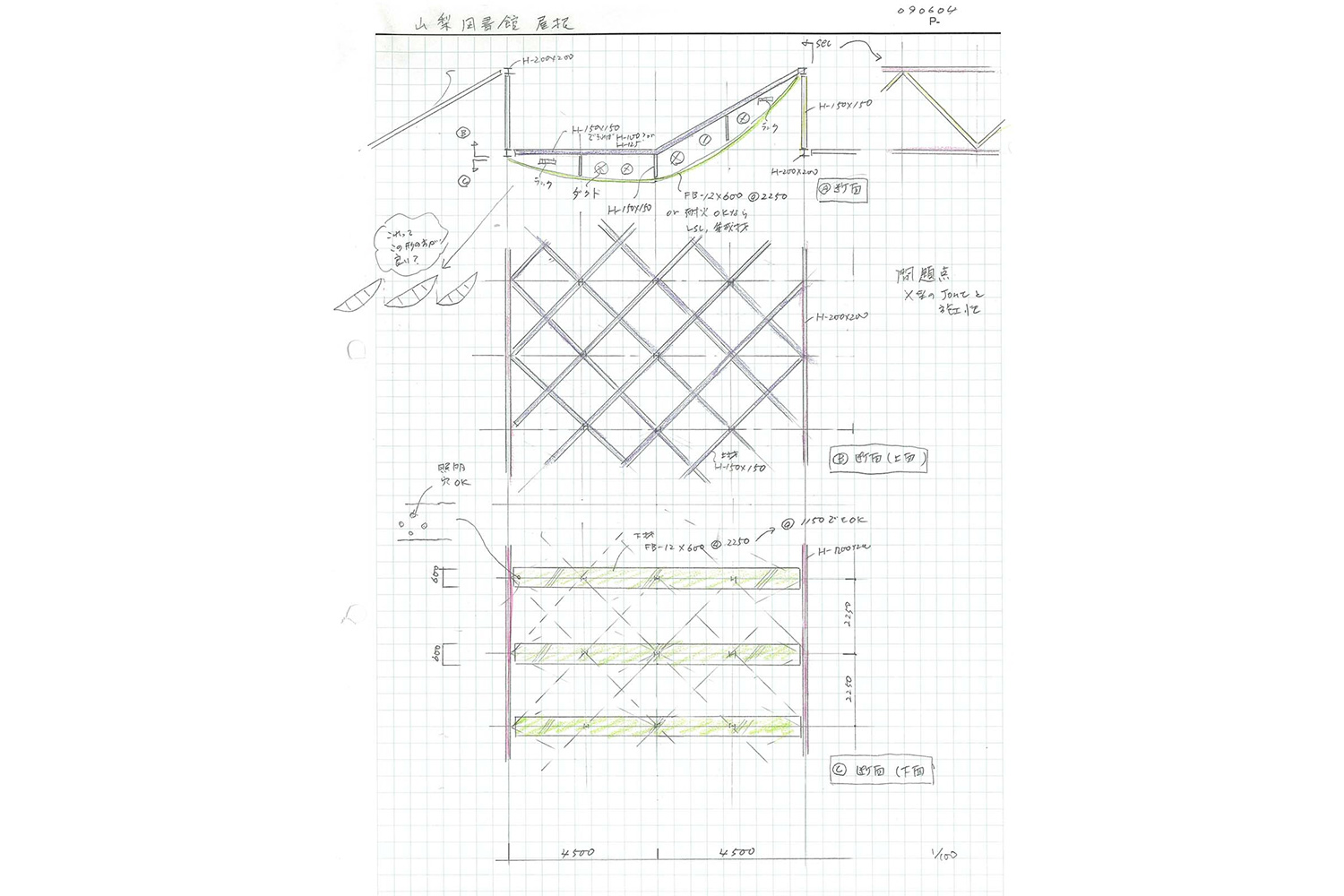

We wanted to create a thin, inconspicuous roof that would nestle into architecture. It spans only 9m, but we cannot make it very thin with simple lattice beams.

From a structural point of view, we proposed a structural frame that prioritizes the visual image of the interior using cage-like lattice patterns. First, we made use of the gaps in the high sidelights placed at 9m intervals in the north-south direction to construct inconspicuous truss beams bridging over 37m the east-west direction. To bring in light from the high sidelights, the upper and lower chords of adjacent truss beams are connected with planer lattice structures (which double as horizontal braces), in combination with band-shaped lower chords drawing gentle curves. For the lower chords, we combined band-shaped members that look like plates at a glance, instead of thin rods or H-shaped steel. By using band-shaped members for the lower chords, instead of thin rods that conversely make them stand out, we thought that we could eliminate the familiar impression of structural members and visually emphasize the lattice structure. We proposed that the 600mm-wide band-shaped members, which form a gentle arc, be naturally bent into a circular arc by taking advantage of the low flexural rigidity along the weak axis that is one of the characteristics of wood members made of laminated wood, LVL, LSL among others.

We were concerned that this proposal would emphasize the structure too much, instead of highlighting the architecture, and the design might deviate from the original concept. Mr. Noguchi responded, "Let me think about it for a while."

The next day, he said, "I would prefer to use steel instead of wood for the loincloth (referring to band-shaped member). Can you still do it?" and that was the final decision. We managed to come up with a convincing proposal. In order to achieve a thinner and shaper appearance, the edges of the band-shaped members were constructed with a box-shaped cross section combining steel flat bars and steel plates.

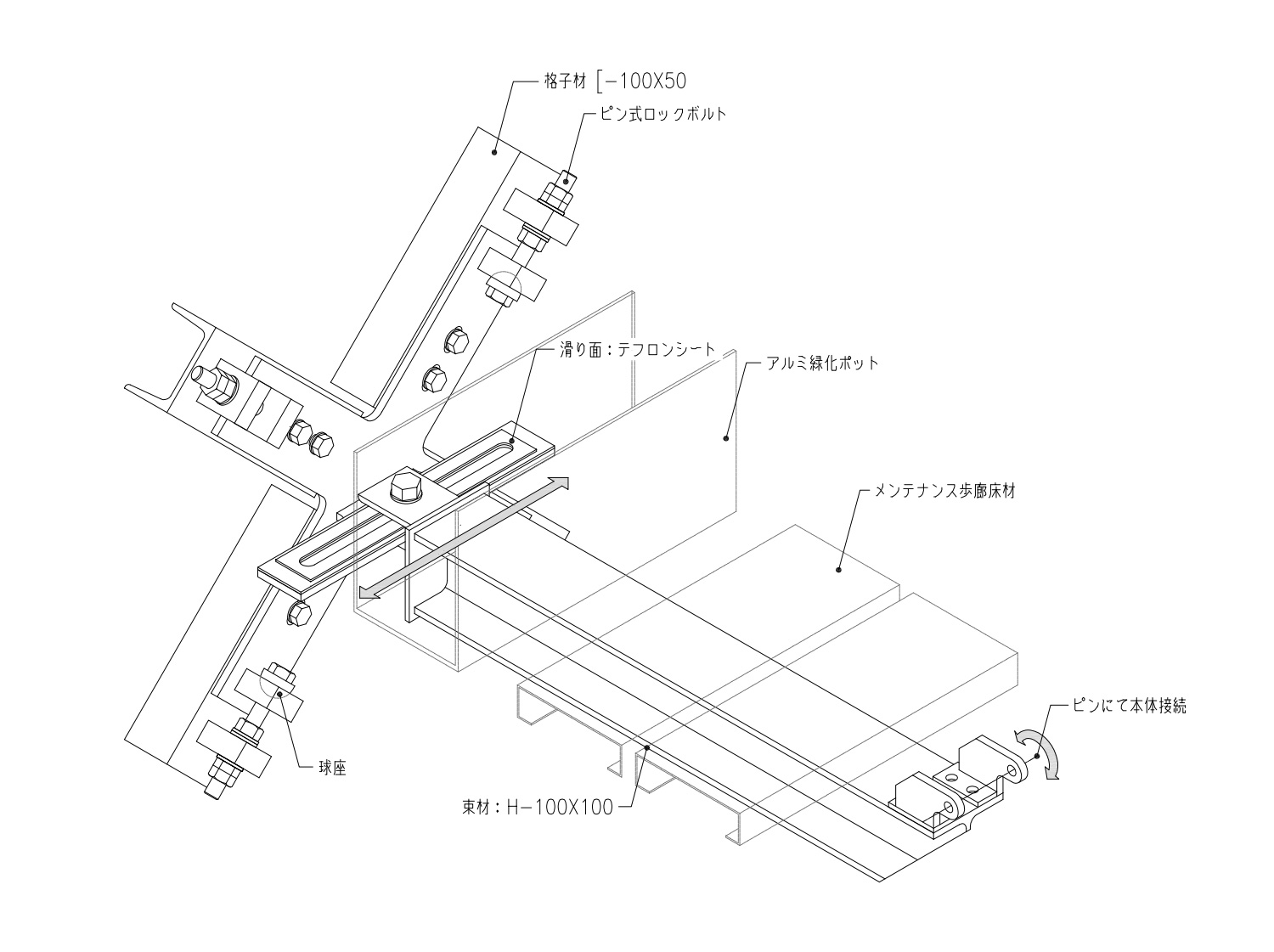

The cage-like lattices covering the west and south walls with built-in pots of vine plants are entirely designed as green curtainwalls over the entire wall. A horizontal loosening mechanism is installed so that the cage-like lattice structure does not bear horizontal forces in the event of an earthquake, and only the constant exterior wall load is suspended from the upper cantilevered beam, which allows for a more delicate structural design. The horizontal forces (seismic force) of the maintenance deck where greening pots are installed are transmitted to the main body of the building through the truss structure with horizontal braces installed under the decks. The horizontal forces (seismic and wind forces) acting in the out-of-plane direction of the lattice planes are mainly transmitted by steel flat bars serving as wind-resistant beams, which are also used as supplementary trusses in the out-of-plane direction, in the same way as the roof. The lattices moves up and down due to thermal expansion in response to the sunlight. Each intersection of the lattices is connected by pin-type lock bolts to absorb rotation, thermal contraction and expansion and release stress.

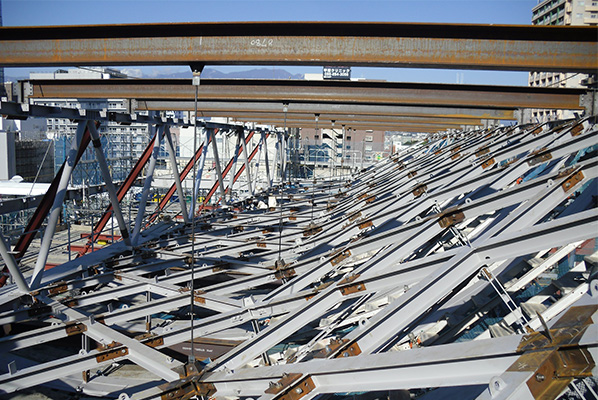

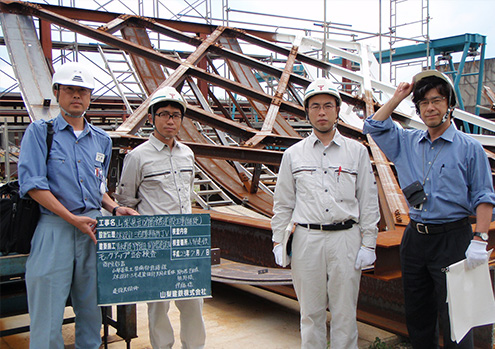

It was decided that a small local steel fabricator would be responsible for the steel fabrication of the roof structure. The steel members made by bending and distorting steel would be exposed and intended to serve as both structural members and design elements. The project began with anxiety and doubt. "It is extremely difficult, but can we really do it?"

In the midst of anxiety, we proceeded to have a meeting over the drawings. ”Can you do this? Can you do that?" In response to our questions, Mr. Ito, Managing Director of Yamanashi Kentetsu, responded with ease, "Yes, we can! We already made a little something." "Really? Let's see... this is great!" This was how the meeting went. While it was not specified in the drawings, they were proactively involved, saying, "Let's make mockups," "We did a test construction" and so on. For the band-shaped lower chords for the roof made by combining steel flat bars (called by nicknames including loincloth, fabric roll, and flat noodle,) they made many test pieces from A to J, and did their best until the very end. In addition, they actively conducted test construction of various parts of the steel frame construction that they were concerned about. We were always overwhelmed by enthusiasm of Managing Director Ito and his staff, and we ourselves were getting more and more enthusiastic as well. Looking up at the roof from inside the completed building, the steel members, full of hidden hardships, are neatly arranged there, which became something we have a special attachment to.

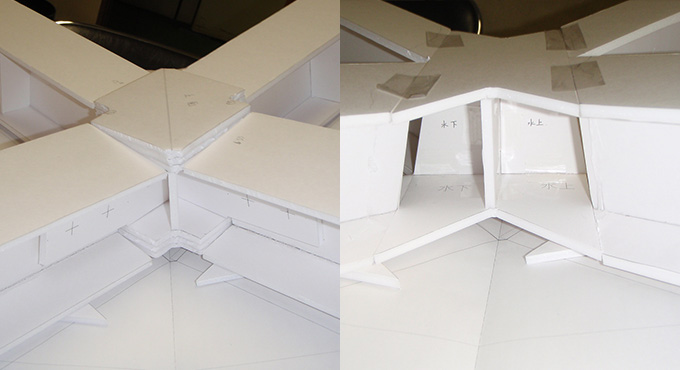

I always think, "An architectural drawing is like a novel." It can be a heartwarming and healing story, love story, coming-of-age story, fantasy, and many other things. Some of them are so dull that I get bored halfway through. When I saw the drawings for the Yamanashi Prefectural Library, I thought, "This is a mystery novel!." And it was a very complicated mystery to solve, and I immediately became absorbed in this mystery novel and started solving it. I was completely captivated. There were only a few hints, not many, only the most essential hints. As I read it over and over again, my mind became completely occupied with this story. I felt the intention of the author (architect). I only come across works like this once every few years. I thought to myself, "I have to somehow decipher this super-complicated mystery." At first, I could recognize anxiety and doubt in the structural engineer's eyes. But I didn't mind that, because I had this novel engrained in my mind." The structural designer's intentions were clarified through endless meetings, and we were almost through solving the mystery. Now, the design. The architect was a big-name in the field at the time, and rarely came to the site for meetings. One day, I learned that the big-name was coming to the site, and I begged the site manager, "Please don't to let him leave, because I am bringing him some models!" I begged him to spare a few minutes of his time and asked him to choose one from the three or four models that I brought. The one he pointed to matched the one I expected. The mystery was almost solved. Now, it was time to start steel fabrication.

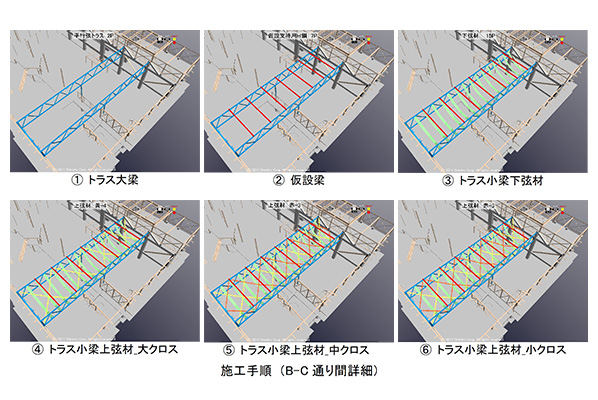

The roof of this building has a structural characteristic that it constantly tends to tilt downwards (from the upper chord to the lower chord of the adjacent truss beams) due to gravity.We knew that depending on the construction method and procedure, the stresses at the time of completion might exceed the values assumed in the design. It was therefore important to make appropriate plans and ensure structural quality. The larger the tilt, the more it will affect the appearance and impair the design quality. In order to achieve the state of stress assumed in the design, the roof erection was planned based on as-built analysis, with the goal of using the minimum number of supports for ease of construction and economy. The main points are the unitization of truss girders, the increased efficiency of lattice joints to be constructed on site, and the use of temporary shape-holding beams and suspension members. In this construction, steel members were assembled with excellent accuracy through measurements.